Encapsulated O Rings

Encapsulated O Rings that are proven to protect the core

M Barnwell Services, the UK’s leading manufacturer, stockist and distributor of Fluid Sealing Products offers a comprehensive range of quality Fluorinated ethylene propylene (Teflon® FEP), PTFE and Perfluoroether (PFA) Encapsulated O Rings.

The design completely encloses a core material and acts as a barrier if any pressure is exerted on the seal. The Encapsulated O Rings is widely used across a range of industries, including Food and Drink (FDA), Chemical Processing, Petrochemical, Pharmaceutical, Paints and Dyes, Refrigeration and Cosmetics. For Cryogenic applications, we also supply the industry-leading Astra Seal.

Available in a wide range of standard Metric and Imperial sizes the Encapsulated O Rings can be supplied as small as 4.5mm ID and with no maximum size. M Barnwell Services Encapsulated O Rings are compliant with FDA, ADI-Free, 3A Sanitary Standards, EU Reg. 1935/2004 and USP Class VI.

We also supply a range of Viton (FKM) FDA and EC1935/2004 & EC2023/2006 Approved, Silicone (VMQ) and EPDM Core with FEP Jacket Encapsulated O Rings.

Seal Profile Options:

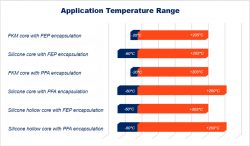

Temperature range chart:

Encapsulated Seal Applications

- Filter Elements

– Filtration is the primary market for encapsulated seals.

– Versatile encapsulated seals are now a standard choice for filter cartridge element neck seals. - Pumps

– PTFE-made pumps utilise encapsulated seals for corrosive material handling.

– Plastic pumps, requiring low-load seals, benefit from hollow-core encapsulated seals. - Mechanical Seals

– While Perfluoroelastomers are common, encapsulated seals serve as a cost-effective alternative in various applications. - Valves

– Widely used in air-operated vent valves, steam valves, and water valves for FDA/WRC compliance. - Mixers and Vessels

– Encapsulated seals on lid seals eliminate the need for expensive molds.

– USP Approval and FDA compliance make them ideal for the pharmaceutical market. - Heat Exchangers

– Tube and shell heat exchangers benefit from Teflon®-jacketed encapsulated seals.

– Popular in food, drink, and pharmaceutical industries due to USP Approval and FDA Compliance. - Flanges

– Encapsulated seals are vital for sealing flanges and apertures.

– For optimal chemical resistance with low compression force support, it is advisable to use hollow-core seals in chemical industry applications.

The M Barnwell Services’ experts can determine if an FEP / PFA encapsulated O Ring is suitable for your particular application. If you would like more information, download our catalogue or contact a member of the team.

We also have over 50 million O Rings and Back-Up Rings in stock. For more information on our range of O Rings click here.

E & OE.