Viton™ O Rings

Available From Stock: Viton™ O Rings, FPM / FKM Seals

M Barnwell Services is one of the UK’s leading stockists and distributors of Viton™ O Rings (and other FKM / FPM Seals). With over 50 million O Rings and Back-Up Rings in stock, we serve over 5000 global customers with swift and dependable deliveries.

Our proficient team manages the entire production process, from prototyping and testing to final part manufacturing. Additionally, we offer specialised certification upon request.

If you would like more information about our range, download our catalogue, or contact a member of the team.

Viton™ O Ring Benefits

- Exceptional resistance to aging and ozone, and have extremely low gas permeability, making them perfect for vacuum applications.

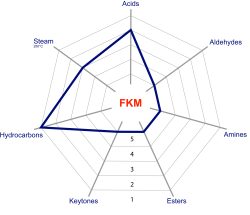

- Self-extinguishing and display resilience against mineral and vegetable oils/greases, acids, fuels, aliphatic, aromatic, and chlorinated hydrocarbons, silicone and non-flammable hydraulic fluids, and many organic solvents and chemicals.

- A temperature range of -20°C to +205°C (intermittent use: -45°C to +230°C.)

- Low gas permeability, low compression set.

Viton™ O Rings are well-suited for diverse sectors, including Agricultural, Automotive, Aerospace and Defence, Petrochemical, Offshore Drilling, and Rail industries.

All these characteristics create a superior seal which you can read more about on the Nitrile (NBR) vs. Viton™ comparison page.

For further details about Viton™ O Rings and FPM / FKM O Rings visit the Material Properties page.

Viton™ O Ring Limitations

- Amines and Anhydrous Ammonia.

- Ketones (MEK, Acetone) and Skdrol fluids.

- Low molecular weight esters and ethers, high-temperature hydrofluoric or chlorosulfonic acids, as well as low molecular weight organic acids (like formic and acetic acids.)

- Polar solvents, low molecular weight organic solvents, and glycol-based brake fluids.

Why Do Industries Use Viton™ O Rings?

Viton™ material excels in the toughest application settings, enduring extreme temperatures and chemical interactions. As a premium, durable fluoroelastomer, it’s a top choice for engineers dealing with challenging conditions, thanks to its proven high performance and exceptional resilience.

More specifically, these seals, widely utilised and uncomplicated, can be spotted in diverse settings, from plumbing and space shuttles to engines, gearboxes, hoses, and pumps. They can serve as face-to-face sealing or as shaft seals, enabling both rotational and linear motion. Viton™ rubber, known for its broad temperature range, boasts exceptional chemical resistance. This makes it an ideal choice for applications like engines, where extreme temperatures and chemical exposure prevail.

Other Viton™ Names

- FKM/FPM (Europe).

- Fluoropolymer.

- Fluoroelastomer.

M Barnwell Services Viton™ Compound Alternatives

- MBMS0254 (Lead-free FKM / FPM)

Properties – Excellent resistance to steam, hot water, and chemicals. Superior sealing performance. Operating Temperature -15°C to +200°C.

Applications – Heat Exchangers, Pulp & Paper processing equipment, Marine diesel engines, Steam/Hot water systems. - MBMS 0056 (High fluorine content FKM/FPM)

Properties – Excellent resistance to fuels and solvents. Operating Temperature -15°C to +250°C.

Applications – Biofuel processing equipment, Marine diesel engines, Heat Exchangers, and Pulp and Paper processing equipment. - MBMS0297 (FKM/FPM)

Properties – Excellent explosive decompression (ED) resistance and low-temperature capability. Tested to NORSOK M-710 standard. Good compression set. With a wide Operating Temperature range -35°C to +225°C.

Applications – Low-temperature and high-pressure applications, Compressors, Subsea Valves & Pumps, Drilling and Exploration equipment. - MBMS0269 (FKM /FPM)

Properties – Explosive decompression (ED) resistance. Tested to NORSOK M-710 standard and TOTAL GS PVV 142 03/01 Also tested to the NACE standards TM0297 (Explosive Decompression) and TM0187 (Sour Gas). With a wide Operating Temperature range of -18°C to +225°C this compound offers outstanding mechanical strength and high-pressure performance.

Applications – High-pressure applications including Blow-out preventers (BOPs), Subsea Valves & Pumps, Drilling and Exploration equipment.

Information About Viton

Viton™ is a trademark of The Chemours Company FC, LLC. M Barnwell Services does not manufacture Viton™ products. There are many grades of DuPont® Viton™ that we have available such as Viton™, Viton™ A, Viton™ B, Viton™ GF, Viton™ GLT, Viton™ GFLT, Viton™ ETP. Common colours include Black, Brown and Green in a variety of shore hardness.

You can learn more about the differences between FKM Seals and Nitrile Seals here – Comparison of two of the most commonly used elastomers – Viton™ O Rings vs Nitrile O Rings. E & OE.