What are Back-up Rings and how to use them?

What are Back-up rings / Anti-extrusion rings?

A Back-up Ring is an inflexible ring that holds an elastomeric seal to its outlined shape and in its right place. They are also called Anti Extrusion Rings and are typically used with O Rings to eliminate extrusion at high pressures.

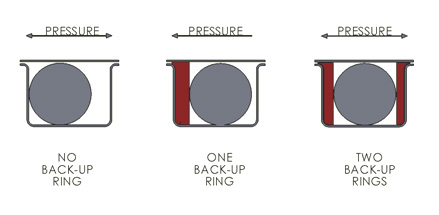

For single acting applications – 1 Back-up Ring is sufficient, however for double acting applications – 2 Back-up Rings are necessary in order to prevent extrusion on both sides.

Back-up Rings are demanded in applications where:

• O Rings of low endurance are installed

• Unfavourable mechanical circumstances are inherent

• Dynamic applications over 100bar

• Static applications around 950bar

• Hydraulic cylinders

• High-pressure hydraulic systems

• High-pressure valves

There are 3 types of PTFE Back-up Rings: Solid, Single Turn and Spiral Cut.

Solid PTFE Back-up Ring may be hard or almost impossible to install, depending on the configuration due to PTFE not being elastic enough. The Back-up ring must be ‘mended’ after it’s installed in the groove to return to its normal dimensions. Single Turn and Spiral Cut Back-up Rings overpass this issue as they can both be opened a little in process of installation without deforming them. PTFE rings in a spiral cut are very popular as it simplifies proper fitting and relatively rejects the extrusion gap in the ring. Furthermore, all split rings are liable to damage during the installation process.

Specifications:

When choosing an adequate Back-up Ring for your application, it is important to be aware of most important specifications:

• Inner dimension of the Ring or the outer dimension of the shaft

• Radial cross-section of the elastomer

• Ring thickness

The use of Back-up Ring may be a practical solution to block the diametrical clearance gap and provide support for the O ring when the stress on it is increased to the point when it can no longer withstand being extruded into the diametrical gap.

A Back-up ring is created from a firmer and more rigid material than the O Ring. It is still however elastic enough to deform under stress to close the extrusion gap. O Ring grooves are dimensionally enlarged in size to contain the use of Back-up Ring(s).

A number of materials can be used for Back-up Rings such as PTFE, metal or hard rubber. PTFE has the benefit of a very low friction in dynamic applications.

M Barnwell Services is the UK’s largest independent stockist, manufacture, and distributor of fluid sealing products and services. For more information about Barnwell O Rings click here

Visit our Back Up Seals / Back Up Rings products for more information.

E & OE. M Barnwell Services endeavours to make sure all the content is correct. Information has been gained from manufacturing partners.