ISO-GARD® Bearing Isolators

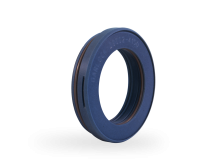

Non-Metallic Bearing Isolator

M Barnwell Services offer the full range of Garlock’s KLOZURE® ISO-GARD® Bearing Isolators. They provide superior bearing protection for motors, pumps, and bearing supported industrial machinery which must perform in the toughest environments.

ISO-GARD® Bearing Isolators are constructed using a filled PTFE material which provides excellent chemical resistance.

Features and Benefits of an ISO-GARD® Bearing Isolator:

- Filled PTFE construction offers superior chemical compatibility

- Unitized construction will not come apart at the time of installation, easy by-hand installation – no need for arbor press or other tools

- Available in a wide selection of configurations (see below)

- Engineered labyrinth design exclude contamination while retaining bearing lubrication – to IP 55 ratings

- Non-contact engineered labyrinth design reduces shaft drag, consequently reducing energy usage

- Compliant with various industry standards

- Non-wearing components – seal properties are not degraded over time, consistent sealing performance

- Extended bearing life, bearing protection increases mean time between failure (MBTF)

- Speedier mean rime to repair (MTTR)

- Eliminates repair for seal housings and shaft grooving

For more information on our range of Bearing Isolators click here or contact a member of the team.

Other Garlock products we supply include GUARDIAN™, MICRO-TEC® II, and SGi® Bearing Isolators, and many more.