KPR Machinery Mounts

KPR Machinery Mounts: Elevate Stability, Conquer Vibrations

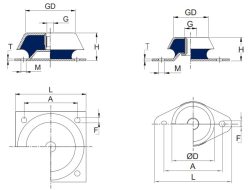

Experience superior isolation from vibrating equipment with our KPR Machinery* Mounts, a revolutionary solution engineered to withstand vertical loads applied in both shear and compression. These mounts redefine standards with a compact design, incorporating an inbuilt bump and rebound control feature to regulate equipment movement during transit. Here are the comprehensive features and diverse applications that position the KPR Captive Flanged Mounts* as the go-to choice for maximum load isolation.

Key Features of KPR Machinery Mounts:

- Compact Design with Bump and Rebound Control:

– The KPR Mounts boast a compact design coupled with an inbuilt bump and rebound control feature.

– This innovative design ensures precise control over equipment movement during transit, enhancing overall stability. - Dome-Shaped Metal Cap for Elastomer Protection:

– A dome-shaped metal cap provides robust protection for the elastomer, shielding it against splashes of oil and fuel contamination.

– This protective feature extends the lifespan of the mount, even in challenging industrial environments. - Compression Design for Airborne Noise Elimination:

– The compression design, combined with the metal cap, effectively eliminates airborne noise, offering a superior alternative to traditional spring mountings.

– This feature ensures a quieter operational environment, particularly crucial in noise-sensitive applications. - Thick Base Flange Metal for Added Strength:

– The KPR Mounts incorporate a thick base flange metal, providing added strength and durability.

– This structural reinforcement enhances the mount’s capacity to withstand varying loads, making it a reliable choice for diverse applications. - Low Height Captive Mounting for Versatility:

– A low-height captive mounting design, capable of accommodating loads ranging from 40kg to 5000kg, ensures versatility across a broad spectrum of equipment.

Applications:

Discover the extensive applications of KPR Machinery Mounts:

- Static and Mobile Generator Sets:

– The KPR Mounts find optimal use in static and mobile generator sets, ensuring unparalleled isolation from vibrations for enhanced performance. - Railway Equipment Compartments:

– In railway equipment compartments, these mounts contribute to a stable and vibration-free environment, ensuring passenger comfort and equipment longevity. - Electronic Control Panels:

– Electronic control panels benefit from the KPR Mounts’ precise control over movement, reducing the risk of damage during transit. - Pumps, Compressors, Centrifugal Fans, and Blowers:

– These mounts are ideal for use in pumps, compressors, centrifugal fans, and blowers, providing effective isolation from vertical loads. - Marine Engines (No Thrust) and Gearboxes:

– In marine applications, where thrust is not a factor, KPR Mounts excel in isolating marine engines and gearboxes from vibrations.

In summary, the KPR Machinery Mounts stand as a pinnacle of innovation, offering unparalleled vertical load isolation for a myriad of applications. Their compact design, protective features, and versatile load-bearing capacity make them an indispensable choice in the realm of equipment stability and performance.

To find out more about our KPR Machinery Mounts, download our Anti-Vibration Mount Brochure or visit our Anti-Vibration Mounts product page.

E & OE. M Barnwell Services endeavours to make sure that all content is correct. We have gathered this information from manufacturing partners.