KPS Shock Mounts

KPS Shock Mounts: Quietly Conquering Vibrations, Elevating Performance

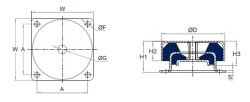

Our KPS Shock Mounts are meticulously crafted to provide robust shock load isolation for electronic equipment in all directions. Designed with innovative features and a high-tensile silicone compound, these mounts ensure optimal performance even in challenging operating conditions.

Key Features of KPS Shock Mounts:

- Top Metal Cover for Element Protection:

– KPS Mounts feature a top metal cover that shields the rubber element from oil and fuel contamination, ensuring the longevity and consistent performance of the mount.

– This protective feature enhances the durability of the mount, making it suitable for demanding electronic equipment applications. - Built-in Bump Rebound Control for Transit Applications:

– Equipped with a built-in bump and rebound control feature, these mounts are specifically designed for transit applications, limiting equipment movement during transport.

– This control mechanism enhances stability, safeguarding electronic equipment from shocks and vibrations during transit. - High-Tensile Silicone Compound for Wide Temperature Range:

– The high-tensile silicone compound used in KPS Mounts enables them to operate in temperatures ranging from -40 to +150 °C.

– This wide temperature range makes these mounts versatile and suitable for electronic equipment exposed to varying environmental conditions. - M5 Fixing Holes for Maximum Flange Strength:

– With M5 fixing holes on the base, KPS Mounts provide maximum flange strength, ensuring a secure and stable connection between the mount and the equipment.

– This design feature contributes to the overall durability and load-bearing capacity of the mounts. - Easy Installation with Low Height Design:

– KPS Mounts are designed for easy installation, thanks to their low height, enabling installation even in areas with restricted access.

– The user-friendly design enhances the overall convenience of integrating these mounts into electronic equipment setups. - Customisable Top Cover Fixing:

– The standard mount comes with an M6 top cover fixing, and an M8 fixing is available on request, providing flexibility to meet specific installation requirements.

Applications:

Discover the diverse applications of KPS Mounts:

- Electronic Equipment Rack Systems:

– KPS Mounts provide robust shock load isolation for electronic equipment rack systems, ensuring stability and protection. - Light Compressors and Pumps:

– In applications involving light compressors and pumps, these mounts contribute to vibration isolation, promoting smooth and efficient operation. - Small Electrical Motors:

– KPS Mounts offer stability and shock load isolation for small electrical motors, enhancing their overall performance. - Air Conditioning Units and Fans:

– In air conditioning units and fan systems, these mounts contribute to stable operation by effectively isolating shock loads. - Vehicle Tool Compartments:

– KPS Mounts find application in vehicle tool compartments, providing stability and shock load isolation for electronic equipment during transportation.