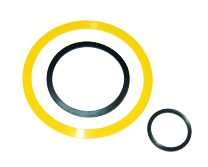

PTFE Back-up Rings

M Barnwell Services’ PTFE Back-up Rings, also referred to as Anti-Extrusion Rings, play a crucial role in bolstering O Rings and X-Rings/Quad-Rings across static and dynamic applications. They effectively counteract seal extrusion caused by high system pressure, a common issue when seals lack support. Typically, Back-up Rings become necessary when system pressures exceed 105 BAR (1500 PSI) or when extrusion gaps are significant.

PTFE Back-up rings serve a protective role rather than sealing. They’re crafted from durable materials to resist extrusion, typically featuring a rectangular shape. Installed alongside elastomeric seals, like O Rings, in static settings, they prevent the extrusion of the elastomeric element under pressure.

Advantages

- High-pressure O Ring applications.

- Low-hardness O Ring materials utilised.

- Compensation for radial sealing gaps.

- Versatile for internal and external sealing, accommodating reciprocating and rotating movements.

- Effective in managing large temperature variations.

- Suitable for both static and dynamic applications.

PTFE Back-up Rings Types

Types of Back-up rings include uncut varieties like the BM and BCM seal types and cut versions like the BG and BCC seal types. Additionally, there are spiral Back-up rings like the SP seal type, each with specific features for different installation needs:

Uncut

- BM Seal Type

External sealing (Bore) Internal sealing (Rod)

– Material: PTFE.

– Rectangular cross-section.

– Standard: AS568, MS27595, JISB2407.

– Static and dynamic applications.

– Reciprocating and rotating movements are possible. - BCM Seal Type

External sealing (Bore) Internal sealing (Rod)

– Material: NBR,FKM,PTFE.

– Concave cross-section.

– Standard: AS568.

– The large contact surface protects the O-Ring against deformation in cases of high pulsating pressure.

– The dimensional stability of the O-Ring improves the sealing force and increases the service life.

– Preferably for static use.

– Reciprocating movements are possible.

Cut

- BG Seal Type

External sealing (Bore) Internal sealing (Rod)

– Material: PTFE.

– Rectangular cross-section.

– Cut angle of 30° or 45° or 20°.

– Static and dynamic use.

– Reciprocating and rotating movements are possible

– Preferred for installations in a closed groove where uncut Back-up Rings are not suitable. - BCC Seal Type

External sealing (Bore) Internal sealing (Rod)

– Material: PTFE.

– Concave cross-section.

– Cut angle of 30° or 45°.

– The large contact surface protects the O-Ring against deformation in cases of high pulsating pressure.

– The dimensional stability of the O-Ring improves the sealing force and increases the service life.

– Preferably for static use.

– Reciprocating movements are possible.

– Preferred for installations in a closed groove where uncut Back-up Rings are not suitable.

Spiral

- SP Seal Type

External sealing (Bore) Internal sealing (Rod)

– Material: PTFE.

– Rectangular cross-section.

– Cut angle of 30° or 45°.

– Consists of standard two spiral windings which are cut at the ends at an angle.

– Static and dynamic use.

– For reciprocating movements only.

– Preferred for installations in a closed groove where uncut Back-up rings are not suitable.

– Compensation of large temperature changes and tolerances without difficulties by a screw-like elongation and contraction.

– Easy Installation in closed grooves for external sealing applications.

– The dimensions are different compared to standard Back-up Rings.

PTFE Back-up Rings Materials

Materials for Back-up rings vary based on application requirements. While standard Back-up rings are made of virgin PTFE, filled PTFE or thermoplastic materials are used for higher loads or sealing against high pressures. Injection-molded options are available for mass production.

Applications and Technical Data

These rings find application across various industries such as:

- Injection Moulding

- Machinery

- Presses

- Excavators

- Agricultural Equipment

- Hydraulic Valves

Technical data specifies their operating parameters including speed, pressure, and temperature range. They can handle speeds up to 2 m/s, pressures ranging from 15 to 250 MPa, and operate within a temperature range of -200°C to +260°C.

Use the following links to find detailed information on our range of Back-up Rings:

For further details on our offerings, access our catalogue, explore the Seal Maker Page, or contact one of our team members. E & OE.