Finite Element Analysis (FEA)

Anticipative behavioural techniques to imitate real-life settings

Finite Element Analysis (FEA) is a computer-based manipulation. It is used to examine engineering applications and sealing elements to perceive their behaviour under several circumstances. This analysis, therefore, entails Finite Element Modelling (FEM). FEM is frequently used for new element design, or to improve an existing product design. Furthermore, virtual medium allows engineers to forecast how sealing elements will function in real-life installations.

FEA normally includes:

- Heat Transfer

- Motion

- Mechanical pressure

- Fluid flow/Mold flow

- Fatigue

- Mechanical vibration

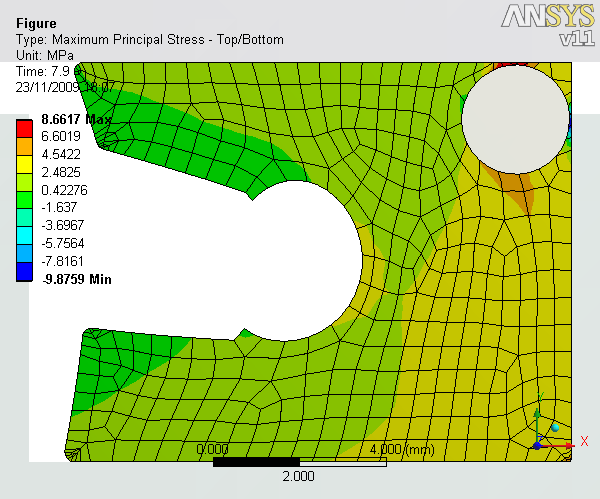

Finite Element Analysis (FEA) is used to forecast contact forces, distortion and pressure points within elastomer components. To increase the precision of modelling, engineers originate temperature specific material prototypes for particular applications. By decreasing pressures within the elastomer, we can lessen the effect of pressure-caused chemical attack and therefore lengthen the life of a component in an installation.

Elastomeric FEA is a niche sphere due to the complex variable features of elastomers in addition to deformation rate and temperature subjection, hysteresis, Mullins-effect and pressure softening. An additional level of complexity is the broad scope of compounds, as each elastomer material presents diverse features. Due to this, our materials are subjected to particular physical checks to gather data needed to interpret them precisely in virtual surroundings.

Being able to choose from an extensive range of in-house elements and a wide supply chain, our production team are able to suggest the best elements for your installation. Either using purely elastomers or reinforcing them with thermoplastics or metals.

FEA supports the designer to address complicated seal geometries, where evaluating the sealing intensity is tough, both instinctively and to evaluate manually. The use of such predictive behavioural schemes can be remarkably advantageous over a wide scope of installations for rubber seals. A number of real-life checks entail complicated set-ups, downtime on equipment or costly laboratory time. The use of FEA helps to exclude or at least speed up the testing scheme. Additionally, it is highly possible to be a more cost-effective technique for evaluating the viability of initiating or changing a seal design.

M Barnwell Services are the UK’s largest independent stockist, manufacturer, and distributor of fluid sealing products and services. For more information about our range, click here or to contact us, click here.

E & OE. M Barnwell Services endeavours to make sure all the content is correct. Information has been gained from manufacturing partners.