How To Fit A Shaft Repair Sleeve

How to remove and install a Shaft Repair Sleeve

This is an instructional guide on the process of how to remove and install a Shaft Repair Sleeve / Redi-Sleeve / Shaft Wear Sleeve. If you are unsure always read the instructions or contact a member of the team today.

Fitting

- Clean the surface where the seal has worn the shaft. File down and polish any burrs or rough spots.

- Measure in three positions the unworn region of the shaft and average the reading in case the shaft is out of round. Select the appropriate sleeve falling within the diameter range from the table that follows. The sleeves are an interference fit on the shaft. No cement is necessary.

- If the shaft is deeply scored, fill the groove with epoxy type filler. Install the sleeve before the filler hardens.

- If the groove does not require filling, apply a light layer of non-hardening sealant to the inner surface of the sleeve.

- Mark the position the sleeve must occupy on the shaft to cover the wear tracks. The sleeve must be placed over the worn area, not just bottomed or left overhanging the end of the shaft or chamfered end.

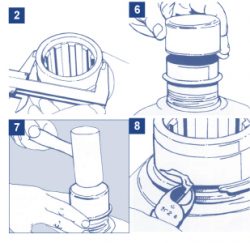

- Place the installation tool over the sleeve. The flange end of the sleeve goes on the shaft first.

- Gently tap the centre of the tool with a mallet until the sleeve covers the seal worn surface. If the installation tool supplied with the sleeve is too short, a length of pipe or tubing with a squared-off, burr-free end can be substituted.

- Unless clearance is required leave the sleeve flange intact. Use side cutters to pry the flange away from the seal surface and twist it into a coil. The flange will break loose along the pre-cut line.

- Check the shaft for burrs (which could damage the seal).

- Lubricate the end of the sleeve when installing the seal.

- Proceed with seal and bearing installation.

Removal

Suggested methods of removal include:

- Heating – which will often cause the sleeve to expand sufficiently to permit removal

- Wire cutters – which may be effective to “rip” or “tear” the sleeve from the shaft by starting at or near the flange, using a twisting motion

- Stretching – with the flange removed, use a small ballpeen hammer to “peen” one or more lines across the full width of the sleeve

M Barnwell Services offers an extensive range of high quality, easy to install stainless steel Shaft Wear Sleeves / Shaft Repair Kits / Redi-Sleeves, designed to provide fast, low-cost solutions. For applications that require an even higher level of abrasion, a specialist range of SKF Gold Sleeves are also available from stock.

For more information on our superb range of stocked Shaft Repair Kits, download the brochure or contact us today.