Aflas® Seals UK

Aflas® Seals UK (TFE/P) – O Rings & Gaskets Specialists

M Barnwell Services are the largest independent manufacturer, stockist and distributor of fluid sealing products in the UK. We stock and supply a range of Aflas® Seals (TFE/P) that are designed for many applications in industries such as Aerospace and Defence, Chemical, General Industrial Environments, and Offshore Drilling.

We provide the most diverse material options in the market and can supply Aflas® Seals (TFE/P) in many sizes for specialty performance. Combine that with our team of experts and we will offer you the right seal for your application.

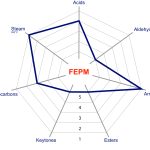

Aflas® is a form of Fluoroelastomer (copolymer of Tetrafluoroethylene-Propylene), which is known for its great overall resistance to a wide range of chemicals including alkalis, amines, methanol, acid, and steam. It’s the material of choice for products and systems that need to operate in rather rough conditions. Therefore, they are used worldwide in all sorts of industrial applications where utmost reliability is demanded, along with the elastic features of synthetic rubber. It is established on an alternating copolymer of tetrafluoroethylene and propylene.

Aflas Seals Grades:

- AFLAS® 100 Series – high molecular scale gives high mechanical durability. Adequate for transfer moulding, compression moulding, and extrusion. The texture is identical to that of AFLAS® 150 below

- AFLAS® 150 Series – exquisite electrical insulation features and chemical resistance. Convenient for transfer moulding, compression moulding, and extrusion

- AFLAS® 300 Series – translucent white base resin with a unique termonomer. Can be pigmented, has superior durability and gives a sleek surface finish. Suitable for extrusion

- AFLAS®400E (development grade) – with new ‘rapid cure’ technology. Can be pigmented. Suitable for extrusion

- AFLAS® 600X (development grade) – with new ‘rapid cure’ technology. Eminent tear strength, compression set, and superior mould release. Perfect for high temperature (HPHT) and high-pressure applications in rough environments where 25 years of service life is demanded. Suitable for compression moulding.

If you would like more information about our range, download our catalogue, visit the Seal Maker Page or contact a member of the team.

E & OE.