ISO3601-3

ISO3601-3: Quality acceptance criteria

ISO3601-3 defines the quality acceptance criteria for O Rings used in fluid systems, the sizes of which are standardized in ISO3601-1 and ISO3601-2.

This section of ISO3601 additionally specifies and classifies surface deficiencies on O Rings and defines the maximum satisfactory limit for these deficiencies.

ISO3601-3 is also suitable to O Rings used in aerospace construction.

GRADES

Grade N (general purpose): defines acceptance guidelines for O Rings designed for general use

Grade S (special): defines acceptance guidelines for O Rings designed for installations demanding a higher level of precision and/or quality in regards to dimensional tolerances of surface deficiencies. Automotive and Critical Industrial applications are an example.

Grade CS (critical service): defines acceptance guidelines for O Rings designed for installations where a high level of precision and/or quality is required with regards to surface deficiencies and dimensional tolerances. A good example of this grade application is medical or critical aerospace, in which the surface of an O Ring must be virtually ideal to execute in an acceptable way.

SELECTION OF GRADE

Grade N will be presumed to be the quality demand if the customer doesn’t specify their requirements, however, in the case of specific aerospace applications, Grade S will be presumed.

SURFACE CONDITION

Surfaces of the O Ring should not have any ruptures, blisters, cracks or other deficiencies that are larger than the limits specified by ISO3601-3. The method used is – a ring that is unstretched is revised under an x2 magnifier with sufficient illumination, however, tactics differ and are usually agreed between customer and manufacturer.

No foreign material sitting on the surface that is apparent under the revision conditions mentioned above

Indentations, non-fills and flow marks within the specified limits should not be permitted in the following situations:

- They interconnect

- There are over 3 in any 25mm range of circumference for grades N and S

- There is over 1 in any 25mm range of circumference for grade CS

- There are more than 3 that are distanced from each other by the extent that is less than the maximum limiting dimensions of such deficiency for grades N and S

- There are more than 2 that are distanced from each other by the extent that is less than the maximum restricting dimensions of such deficiency and only 1 per 25mm extent of circumference for grade CS

No flow marks that are in effect radially orientated.

The surface consequent from any extreme trimming should be blended smoothly.

Wire gauges of the adequate size may be used to establish the size of the flaws by comparison.

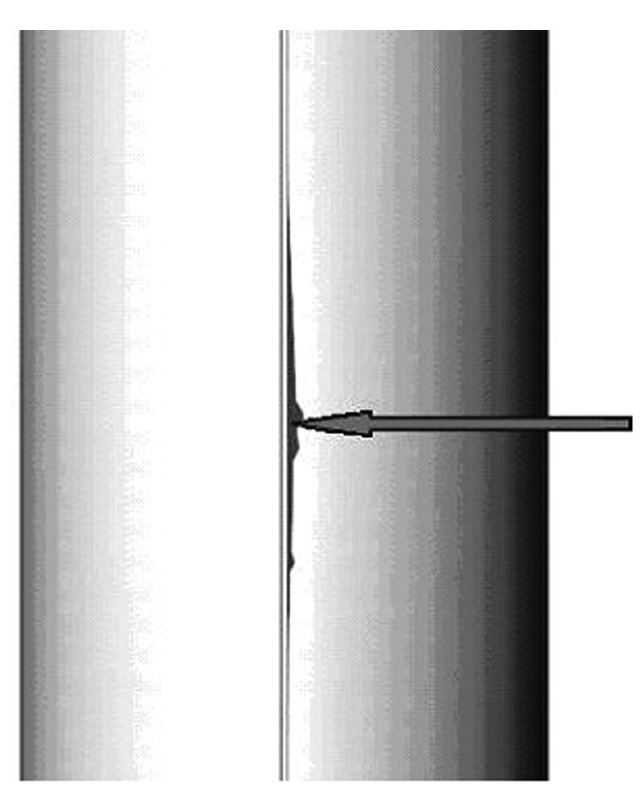

BACKRIND

Acceptable within dimensional limits for Grade N and Grade S O Rings

Unacceptable for Grade CS O Ring

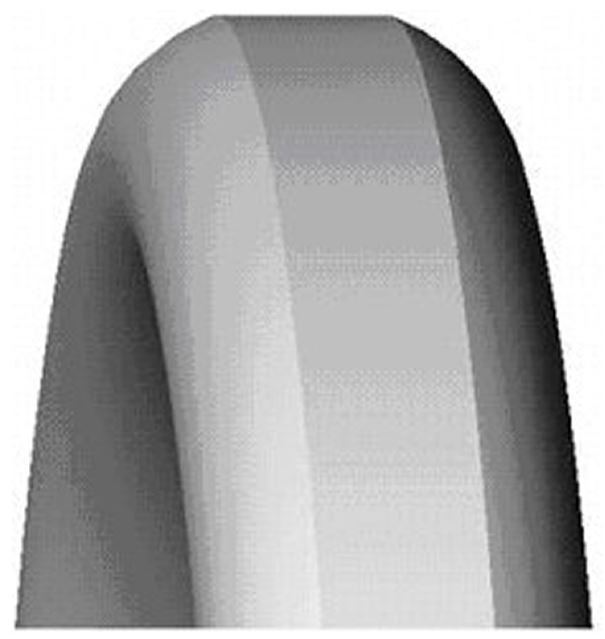

TRIMMING

Acceptable excessive trimming

Unacceptable excessive trimming

FLASH

Unacceptable for CS O Rings

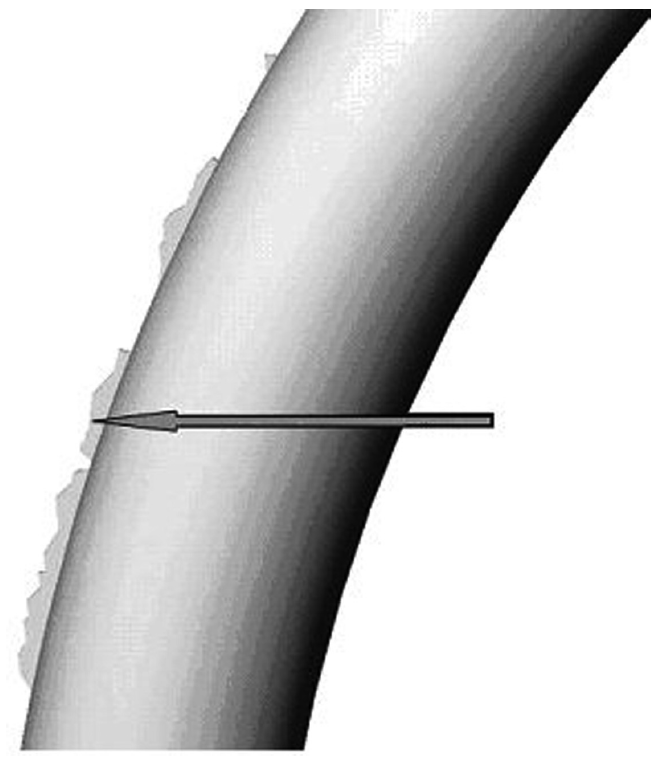

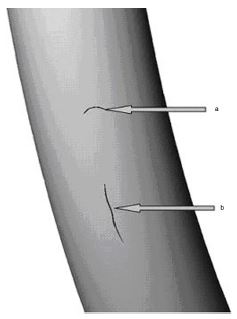

FLOW MARKS

a – radial orientation of flow mark is unacceptable

b – acceptable within dimensional limits

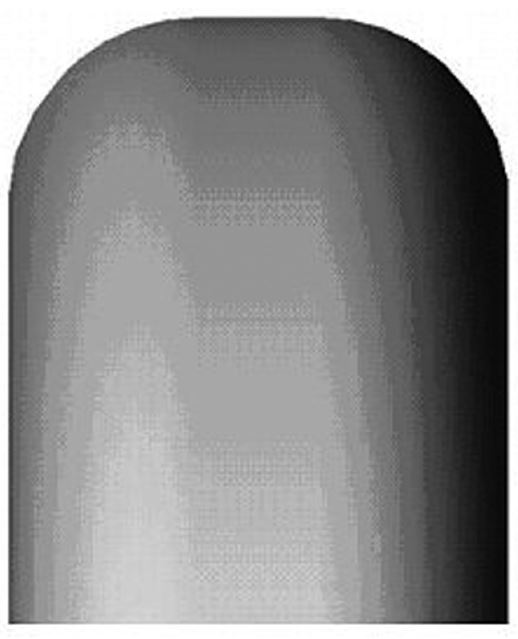

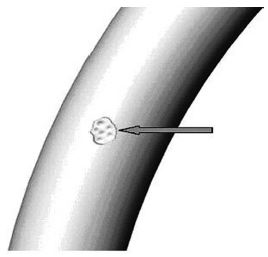

MOULD DEPOSIT INDENTATION

Acceptable within dimensional limits

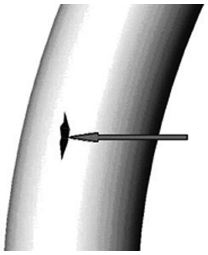

NON-FILLS, INCLUSIONS, AND INDENTATIONS

Acceptable within dimensional limits

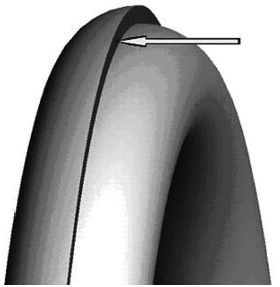

OFF-REGISTER / MISMATCH

Acceptable within dimensional limits

Click here to see the ISO3601 overview (Pt1, Pt2, Pt3, Pt4, Pt5).

If you require additional information about our range and/or services, download our catalogue or contact a member of the team.

E & OE. M Barnwell Services endeavour to make sure that all content is correct. Information has been gathered from manufacturing partners.