What is Rapid Gas Decompression (RGD)

What is Rapid Gas Decompression (RGD)? What are the causes? How it affects elastomers?

What is Rapid Gas Decompression (RGD)? or What is Explosive Decompression (ED)?

Rapid Gas Decompression (RGD) is an occurrence that frequently appears whilst high-stress gas particles drift into the elastomer in the concentrated/compressed form. When the stress ambient to the elastomer is quickly relieved, the compressed gas inside the rubber attempts to broaden and escape from the elastomer, consequently causing Rapid Gas Decompression (RGD). The detrimental effect of this swelling is not so much throughout the intake of the gas, but mostly while the system stress is rapidly released. In the occurrence of Explosive Decompression (ED), the gas immersed by the polymer broadens suddenly inside the polymer upon the alleviation of surrounding stress.

Resulting from aggressive carbon dioxide and hydrogen sulfide gases, Rapid Gas Decompression (RGD) causes degeneration and collapses of polymer elements, at the same time putting costly machinery and assets at risk. Such failure can arise in down-hole installations, gas compressors and further circumstances where high stress is routinely confronted. Due to their persistent stress imbalance, elastomers are most fragile to RGD. Once they are compressed, gases permeate into the inside of the seal, where they stay until stress is alleviated. When this occurs, the gas is pushed to exit via the easiest route, frequently causing failures and ruptures of elastomers and other parts.

Damage to rubber seals as a result of Rapid Gas Decompression is a frequent issue in the Oil & Gas industry and high-stress gas installations. Furthermore, materials used for those installations are vulnerable to high stress, high temperatures and various corrosive gases and fluids.

M Barnwell Services has supplied RGD resistant elastomers to many major manufacturers of pumps, turbine driven compressors, gas re-injection appliances and other manufacturers who must lessen the consequences of high-stress gases in their machinery.

Rapid Gas Decompression (RGD) standards

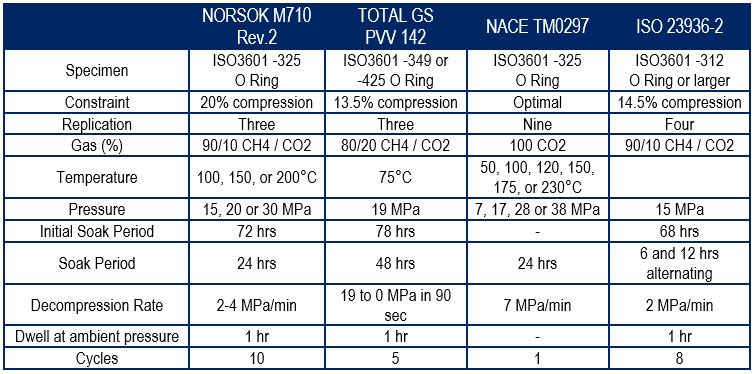

- NORSOK M-710 rev 2 section 7.3 annex B: “Qualification of Non-metallic Sealing Materials and Manufacturers – Resistance to rapid gas decompression (RGD)”

- ISO 23936-2: “Petroleum, petrochemical and natural gas industries – Non-metallic materials in contact with media related to oil and gas production – Part 2: Elastomers.”

- NACE TM0297: “Effects of High Temperature, High-Pressure Carbon Dioxide Decompression on Elastomeric Materials.”

- TOTAL General Specification GS PVV 142 Appendix 8: “Elastomer O-ring Seals Explosion Decompression Type Testing Procedure”

Rapid Gas Decompression (RGD) Resistant Elastomers

- 90 durometer, versatile FKM – tested to NORSOK M710 Rev.2, TOTAL GS PVV 142, NACE TM0297 and ISO 23936-2

- 90 durometer, low-temperature FKM – tested to NORSOK M710 Rev.2, TOTAL GS PVV 142, NACE TM0297 and ISO 23936-2

- 90 durometer, ultra-low temperature FKM – tested to NORSOK M710 Rev.2, TOTAL GS PVV 142, NACE TM0297 and ISO 23936-2

- 90 durometer, Aflas® based FEPM – tested to NORSOK M710 Rev.2, TOTAL GS PVV 142, NACE TM0297 and ISO 23936-2

- 90 durometer, medium ACN, HNBR – tested to NORSOK M710 Rev.2, TOTAL GS PVV 142, NACE TM0297 and ISO 23936-2

- 87 durometer, low ACN, low temperature, HNBR – tested to NORSOK M710 Rev.2 and ISO 23936-2

- 85 durometer, low ACN, low-temperature HNBR – tested to NACE TM0297

- 90 durometer, steam res. EPDM – tested to NACE TM0297

- 90 durometer FFKM – tested to NORSOK M710 Rev.2, TOTAL GS PVV 142, NACE TM0297

- 90 durometer, low-temperature FFKM – NORSOK M710 Rev.2, TOTAL GS PVV 142, NACE TM0297

We hope this information helps you answer the question What is Rapid Gas Decompression?

If you require additional information about our range and/or services, download our catalogue or contact a member of the team.

For more information on Seal Failure Modes, click here.

E & OE. M Barnwell Services endeavours to make sure that all the content is correct. Information gained from manufacturing partners.